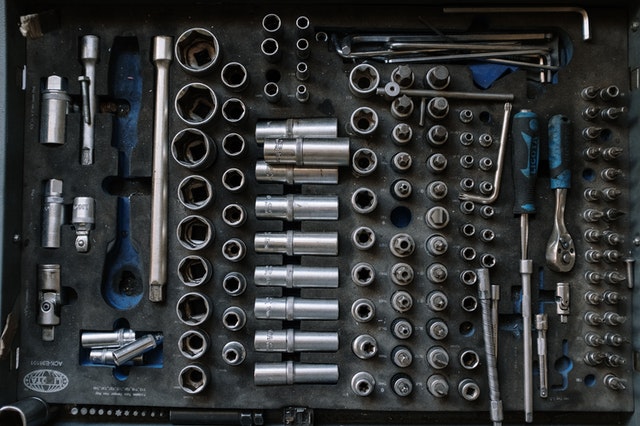

How to Start Restoring Old Tools

On October 30, 2021 by Walter PowellDo you have some old power tools lying around? Maybe you bought a used orbital sander at a garage sale and want to get it back up and running. Depending on the make and model, repairs can be performed with patience and some practical know-how. Older tools tend to be more durable and were designed to be repaired. So, even that antique jointer that’s in your attic has a chance at a second life.

There are no rules that can apply to restoring every single tool out there, but there are some good general guidelines. This article will lay out some of the basics of tool restoration so that you can breathe some life back into the tools you thought were out of commission.

Choose the Right Brand

First, if you know that you can find replacement parts, your job will be a lot easier. There’s a reason that certain brands are more popular with tool restorers. The most popular brands churned out a ton of high-quality tools at reasonable prices, so finding replacement parts shouldn’t be too hard. Look for well-established brands with a sizeable online presence amongst collectors.

Clean and Lubricate

Next, it’s vital to clean up your tool and get the parts lubricated. You’ll want to use something like a Clean Plast Purge compound Noblesville IN to get the rust and burn marks removed. A dry lubricant should be applied to all the moving parts, and all the dirt should be scrubbed off.

Repair With Caution

If you have the skill, repair any damaged parts. However, not everything needs to look brand new. If the tool safely functions, any cosmetic modifications can negatively affect the resell value of the instrument.

Repairing decommissioned tools is a great way to learn basic technical skills and get some value out of forgotten treasures. It’s easier than you might think, so don’t be afraid to tinker.

Archives

- April 2024

- March 2024

- February 2024

- January 2024

- December 2023

- November 2023

- October 2023

- September 2023

- August 2023

- July 2023

- June 2023

- May 2023

- April 2023

- March 2023

- February 2023

- January 2023

- December 2022

- November 2022

- October 2022

- September 2022

- August 2022

- July 2022

- June 2022

- May 2022

- April 2022

- March 2022

- February 2022

- January 2022

- December 2021

- November 2021

- October 2021

- September 2021

- August 2021

- July 2021

- June 2021

- May 2021

- April 2021

- March 2021

- January 2021

- December 2020

- November 2020

- October 2020

- September 2020

- July 2020